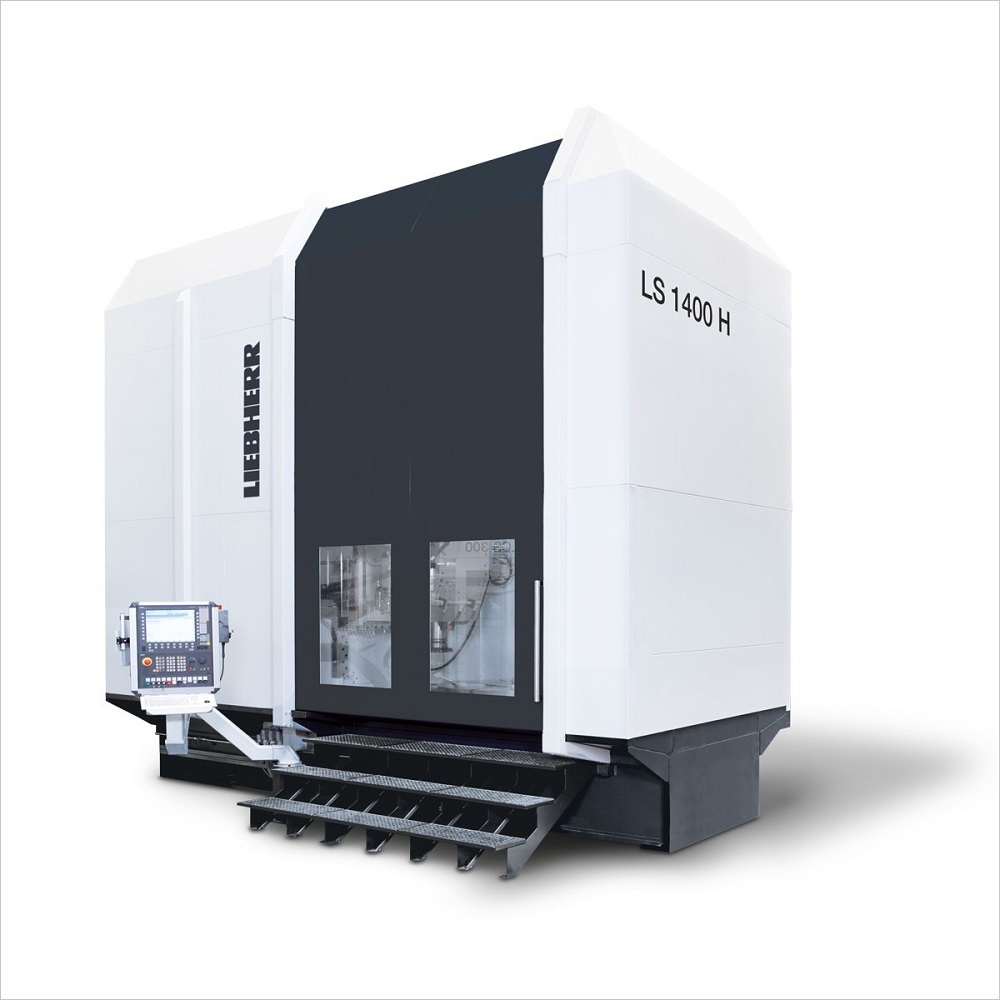

Liebherr – Gear Shaping – LS Series

With the machines LS 80 – LS 180 Liebherr is introducing a new series of production gear shaping machines. The performance and flexibility of these machines are optimized for high production requirements.

The machines are based on a common modular platform with proven components from the hobbing machine platform. Especially noteworthy are the direct table drive and the thermo-symetric, liquid-circulated machine bed.

For small face width parts, a RAPID version with max. 3000 strokes/min. is available. For tapered gears all models can be equipped with a swivel-type column for up to 12 swivel angle.

For the dry machining process, efficient and fast chip separation is a major prerequisite. The process energy involved and the disposal of hot chips should not adversely affect the geometry of the machine. The redesigned work area with stainless steel lining improves the chip discharge.

The extremely short cutting times require short loading and unloading times. Modular automation systems are available for various types of workpieces, supplemented by integrated and peripheral workpiece storage systems.

Key Features

- The machine bed serves as platform for various gearing technologies.

- Our backlash free and high dynamic gear driven table drives meet all demands regarding speed and accuracy.

- Machines are delivered with Siemenscontrol in connection with Siemens-drives.

- The tailstock column enables manual and automatic loading / unloading of bore- and shaft-type parts for dry and wet machining.

- The high performance of the machine requires low downtimes and an easy maintainability.

Available Models

Key Industries

- Machinery & Manufacturing

More Products

Liebherr-Verzahntechnik GmbH, founded in 1969, is one of the leading manufacturers of machine tools and automation systems. The company offers…