Escomatic – CNC – NM6 Flexi

Unveiled on the 5th of October 2015 at the EMO in Milan, a new machine comes to complete the renewal of the escomatic products. This machine takes its place in the center of the Esco SA range between the DX CNC (escomatic D2 / D5 CNC, D5 Ultra, D5 TWIN) and the EC (escomatic EC 8). It will succeed the New Mach 64x range which has held a successful position for many years.

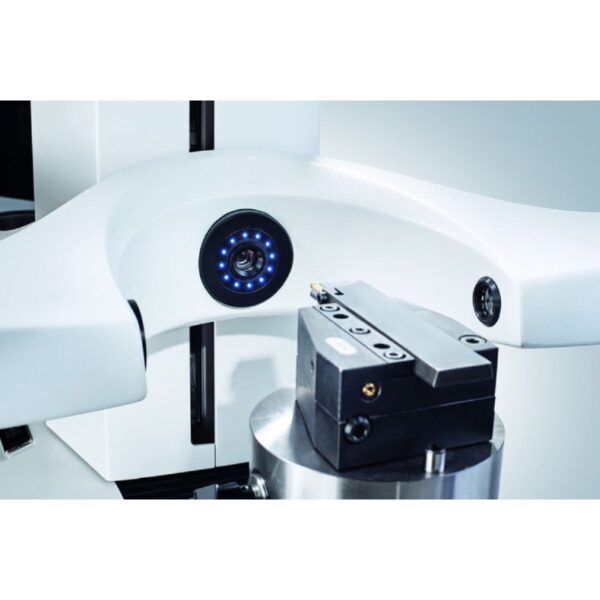

The Escomatic NM6 Flexi took over the high-performance tool head of the New Mach range as working base.

Technical Specifications

| Turning | Secondary operations |

|---|---|

| Max material diameter : 6.50 mm | Number of front slides axial : 3 (+1 lateral option) |

| Work piece length standard : 150 mm | Number of rear spindles axial : 4 (+2 vertical option) + 2 or 4 tool holders |

| Number of tools : 4 | Max speed of counter spindle : 10’000 t/min. |

| Max tool head speed : 10’000 t/min. (12’000 option) | Included : C and Y-Axis |

Key Features

- More flexible, thanks to the possibility to program the secondary slides independently and because the straightening can be controlled and adjusted from the console

- Easier, through a wide-open access for the operator and the use of the latest programming technologies FANUC 0i-TF.

- Faster, because the independent functioning of the two front and back units will ensure for improved cycle times.

Key Industries

- Aerospace

- Automotive

- Machinery & Manufacturing

- Energy

- Semiconductor, Solar & Electronics

More Products

For over 60 years, the ESCO company has been dedicated to and specialized in the development and manufacturing of automatic…