The mechanical engineering company is the global market and technology leader in its areas. These include the development and manufacture of machines for the production of bevel and cylindrical gears, measuring centers for axially symmetrical obje…

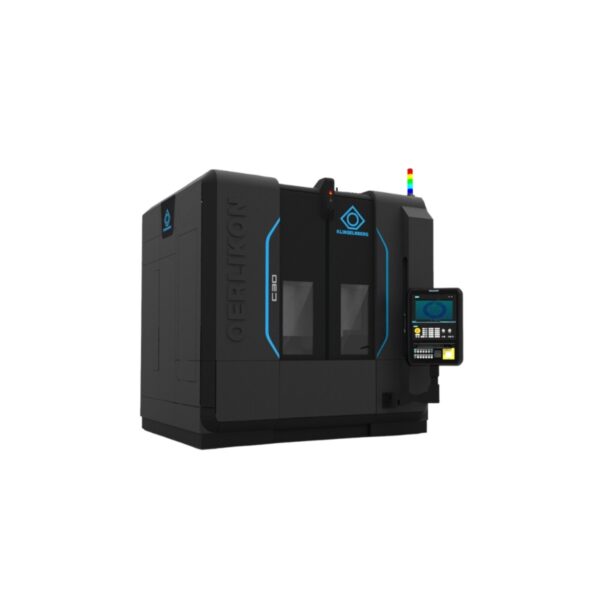

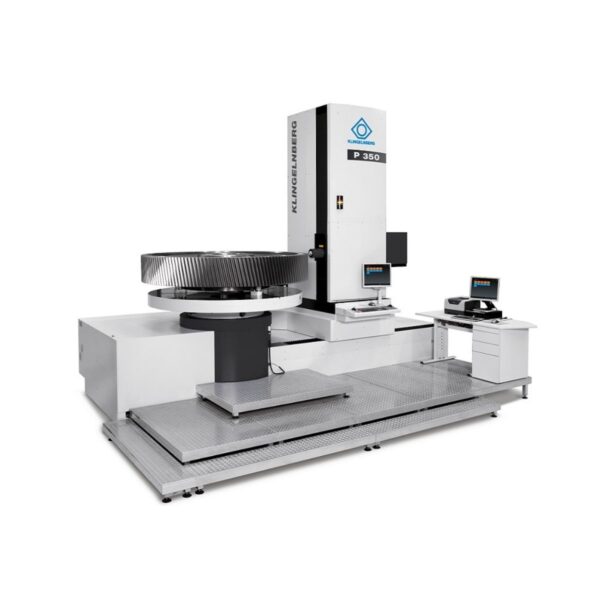

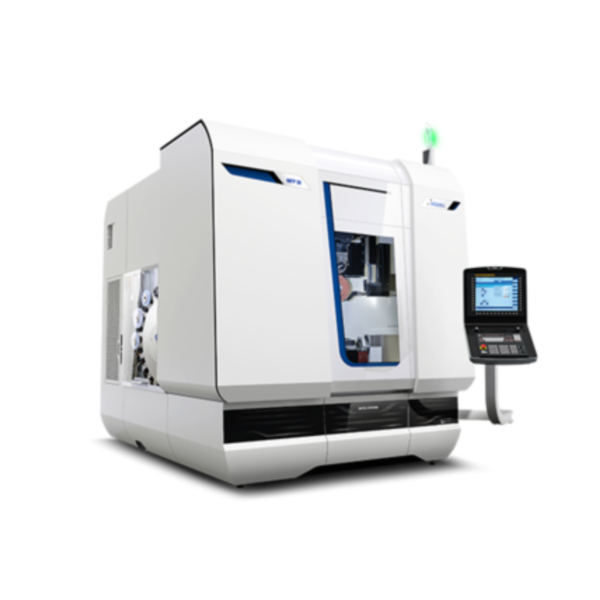

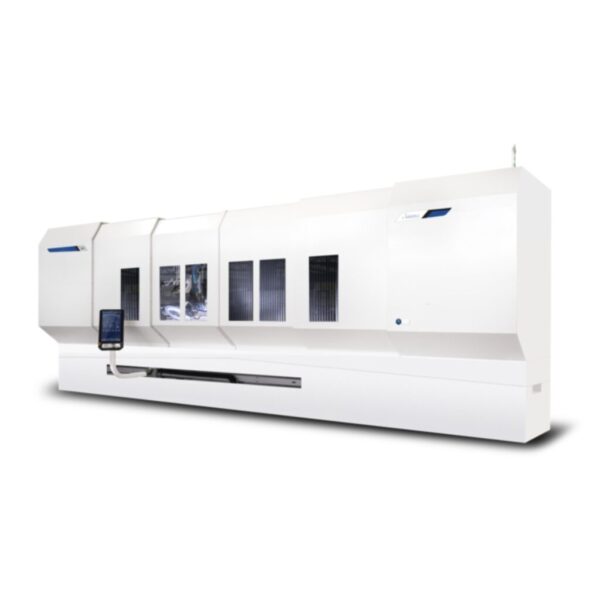

The mechanical engineering company is the global market and technology leader in its areas. These include the development and manufacture of machines for the production of bevel and cylindrical gears, measuring centers for axially symmetrical objects of all types, and the production of high-precision gear components made to customers’ orders.

Today Klingelnberg operates engineering and manufacturing facilities in Zurich, Switzerland, Hueckeswagen and Ettlingen, Germany, and Gyoer, Hungary. The company maintains a global presence with Sales and Service offices in Italy, France, Spain, Russia, Japan, India, China, Brazil, the United States, and Mexico.

The company’s declared aim is to continue to provide highly efficient, competitive products for customers and partners from a range of industries, including the automotive, commercial vehicle and aircraft industries, shipbuilding, the wind-power industry, and general gear manufacturing. In all its dealings, Klingelnberg is respectful of the environment – as evidenced by its ISO 14001 certification and participation in the Blue Competence Initiative by the German Engineering Federation (VDMA).