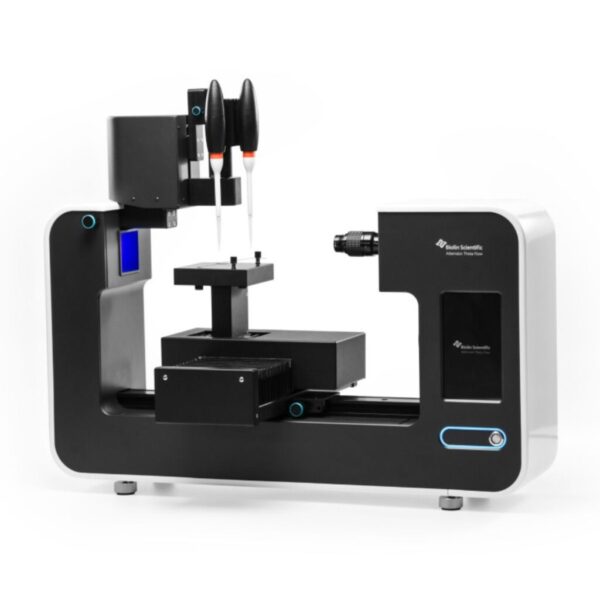

Biochrom – UV/Visible Spectrophotometry – WPA series

An established international brand, Biochrom WPA has innovative spectrophotometers and colorimeters designed to meet the varied needs of cutting-edge life science laboratories, general laboratories, science education in schools and colleges, and t…

An established international brand, Biochrom WPA has innovative spectrophotometers and colorimeters designed to meet the varied needs of cutting-edge life science laboratories, general laboratories, science education in schools and colleges, and tropical medicine clinics.