Idex – Flat-Bottom Fittings – VacuTight™ Fittings

VacuTight Fittings are designed to provide airtight, dependable connections under vacuum and low pressure conditions. Many of the VacuTight Nuts have streamlined profiles for use in systems requiring a large number of connections in a small area. …

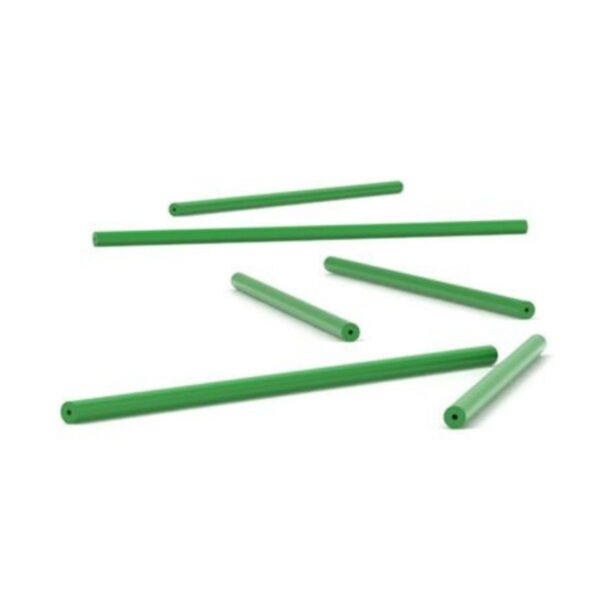

VacuTight Fittings are designed to provide airtight, dependable connections under vacuum and low pressure conditions. Many of the VacuTight Nuts have streamlined profiles for use in systems requiring a large number of connections in a small area. Furthermore, the VacuTight Ferrule’s small size ensures sufficient nut/thread engagement, even in shallow ports. These features make VacuTight Fittings ideal for “combichem” high throughput screening, clinical diagnostic, and other automated liquid handling applications.