Idex – Flow Regulating Valves – Check Valves

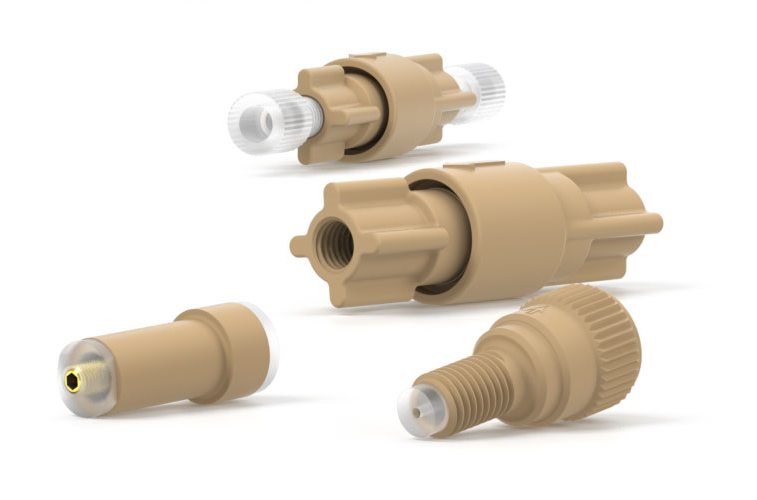

In many applications, there is a need to limit the fluid flow to one direction. Check valves are the perfect solution for this need. Several versions are available, including our standard check valves, our non-metallic check valves, and even some specialized luer-based check valves. Check Valves are designed to effectively deliver a low cracking pressure. Most of our Check Valves connect directly to any 1/4-28 flat-bottom port. We created this unique design to eliminate the need for additional tubing cuts and connections to install traditional check valves. They accept fittings with 1/32 inches, 1/16 inches, 1/8 inches or 1.0 to 3.0 mm outer diameter tubing.

Available Models

Inline Cartridge Check Valves are designed to limit flow in one direction and deliver a low cracking pressure. Ideal placement for these valves would be on the effluent side of the column to prevent post-column derivatization agents from flowing back and poisoning the column if the HPLC mobile phase pump were to shut down.

- Check Valve Inline Assembly With Fittings

- Check Valve Inline Assembly Without Fittings

Inline Cartridge Check Valves are designed to limit flow in one direction and deliver a low cracking pressure. Ideal placement for the CV-3000 would be on the effluent side of the column to prevent post-column derivatization agents from flowing back and poisoning the column if the HPLC mobile phase pump were to shut down. It includes (1) CV-3001 Cartridge and (2)OD x P-215 Flangeless Fittings for 1/16″OD tubing

Technical Specifications

| Swept Volume µL | 96 |

| Thread Port Configuration Flat-Bottom | 1/4-28 |

| Material | PEEK, perfluoroelastomer, gold-plated stainless steel |

| Cracking Pressure (psi) | 1.5 |

| Cracking Pressure (bar) | 0.1 |

| Pressure Rating Max (psi) | 1000 |

| Pressure Rating Max (bar) | 69 |

| For Tubing outer diameter (inches) | 1/16 |

- Check Valve Inline Assembly 3 psi

Our Inline Check Valve Assembly is designed to optimally limit flow in one direction. Our valve is strong and durable and delivers a 3 psi cracking pressure. It includes (1) CV-3001 Cartridge and (2)OD x P-315 Flangeless Fittings for 1/8″OD tubing.

Technical Specifications

| Swept Volume µL | 100 |

| Thread Port Configuration Flat-Bottom | 1/4-28 |

| Material | PEEK, perfluoroelastomer, gold-plated stainless steel, ethylene propylene |

| Cracking Pressure (psi) | 3 |

| Cracking Pressure (bar) | 0.2 |

| Pressure Rating Max (psi) | 1000 |

| Pressure Rating Max (bar) | 69 |

| For Tubing outer diameter (inches) | 1/8 |

- Check Valve Inline Cartridge, Cracking Pressure 1.5 psi/0.1 bar, Swept Volume 91 µL

- Check Valve Inline Cartridge, Cracking Pressure 3 psi/0.2 bar, Swept Volume 92 µL

- Check Valve Inline Cartridge, Cracking Pressure 3 psi/0.2 bar, Swept Volume 16 µL

Inline Cartridge Check Valves are designed to limit flow in one direction and deliver a low cracking pressure (3psi). They are made of biocompatible, inert PEEK and durable ethylene propylene. Each has gold plated stainless steel springs and 1/4-28 thread port configuration. The first Inline Cartridge is for assembly CV-3000 and it’s cracking pressure is 1.5 psi (0.1 bar). The second is for assembly CV-3010. The cracking pressure for the Inline Cartridge is 3 psi (0.2 bar). The last includes (1) CV-3010 Cartridge and (2) XP-315 Flangeless Fittings for 1/8 inches outer diameter tubing.

Technical Specifications

| Thread Port Configuration Flat-Bottom | 1/4-28 |

| Material | PEEK, perfluoroelastomer, gold-plated stainless steel |

| Pressure Rating Max (psi) | 1000 |

| Pressure Rating Max (bar) | 69 |

- Quick Stop Luer Check Valve

Our Quick-Stop Luer Check Valve is specifically designed to provide inline luer connect/disconnect convenience while avoiding spills. It offers Check Valve protection with Luer convenience. It is made from biocompatible PEEK with gold-plated stainless steel spring.

Technical Specifications

| Swept Volume µL | 107 |

| Material | PEEK |

Standard Inline Check Valves adds excellent back-flow protection without additional connections. It delivers low cracking pressure and offers excellent chemical resistance. Connect these Check Valves to any 1/4-28 flat-bottom port. Then thread your 1/4-28 flat-bottom fitting into the check valve to connect the tubing. Once installed, the spring-actuated sealing system eliminates back flow, helping to prevent upstream contamination or damage. In addition, the unique design of this product eliminates the additional tubing cuts and connections required to install conventional inline check valves.

- Check Valve Inlet 1/4-28 Male x 1/4-28 Female, Cracking Pressure 15 psi/1 bar, Swept Volume 20 µL

- Check Valve Inlet Assembly 3 psi 1/4-28 .020, Cracking Pressure 3 psi/0.2 bar, Swept Volume 16 µL

Our standard Inlet Check Valve adds back-flow protection to any 1/4-28 flat-bottom port. Made from PEEK, PCTFE, perfluoroelastomer, PTFE and stainless steel it offers excellent chemical resistance. It’s spring actuated sealing system eliminates back-flow, helping prevents upstream contamination or damage. It has a cracking pressure of 15psi (1 bar)/3psi (0.2 bar) and a 1/4-28 Flat-Bottom Male to 1/4-28 Flat-Bottom Female thread port configuration.

Technical Specifications

| Thread Port Configuration Flat-Bottom | 1/4-28 |

| Material | PEEK, perfluoroelastomer, stainless steel |

| Pressure Rating Max (psi) | 2000 |

| Pressure Rating Max (bar) | 138 |

- Check Valve Outlet Assembly 1/4-28 Male to 1/4-28 Female, Cracking Pressure 15 psi/1 bar, Swept Volume 20 µL

- Check Valve Outlet 3 psi 1/4-28 .020 thru hole, Cracking Pressure 3 psi/0.2 bar, Swept Volume 16 µL

Our standard Outlet Check Valve adds back-flow protection to any 1/4-28 flat-bottom port. Made from PEEK, PCTFE, perfluoroelastomer, PTFE and stainless steel it offers excellent chemical resistance. It’s spring actuated sealing system eliminates back-flow, helping prevents upstream contamination or damage. It has a 1/4-28 Flat-Bottom Male to 1/4-28 Flat-Bottom Female thread port configuration.

Technical Specifications

| Thread Port Configuration Flat-Bottom | 1/4-28 |

| Material | PEEK, perfluoroelastomer, stainless steel, ethylene propylene |

| Pressure Rating Max (psi) | 2000 |

| Pressure Rating Max (bar) | 138 |

- Check Valve Inline Outlet, Cracking Pressure 15 psi/1 bar, Swept Volume 16 µL

Our standard Outlet Check Valve adds back-flow protection to any 10-32 Coned Port. Made from PEEK, PCTFE, perfluoroelastomer, PTFE and stainless steel it offers excellent chemical resistance. It’s spring actuated sealing system eliminates back-flow, helping prevents upstream contamination or damage. It has a cracking pressure of 15psi (1 bar) and a 10-32 Coned Male to 10-32 Coned Female thread port configuration.

Technical Specifications

| Thread Port Configuration Coned | 10-32 |

| Material | PEEK/Perfluoroelastomer |

| Pressure Rating Max (psi) | 2000 |

| Pressure Rating Max (bar) | 138 |

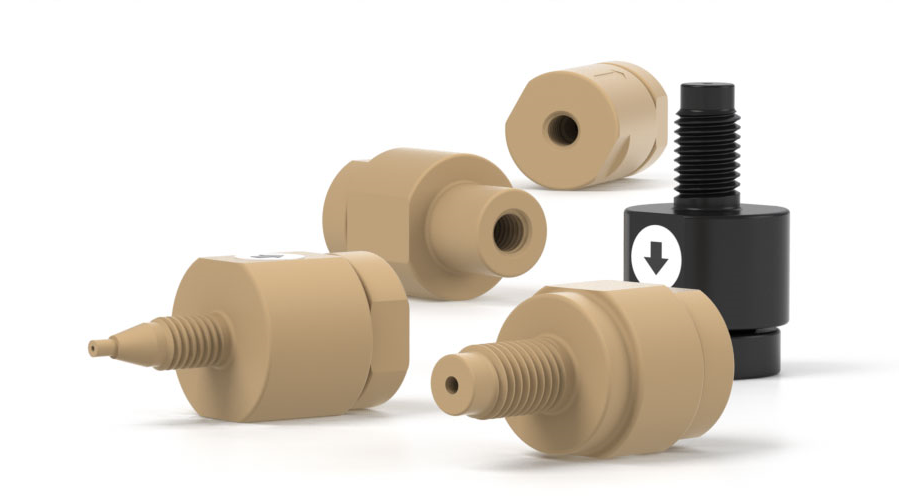

Our Non-Metalic Check Valves are biocompatible and delivers a low cracking pressure. With a swept volume of only 7.4 μL, our Check Valve is perfect for applications where low flow path volume is critical, such as delivery to lab-on-a-chip, single-cell analysis and micro- or nano-LC post-column derivatization. Once installed, this check valve helps prevent back flow and the potential for contamination or damage to sensitive upstream equipment.

- Check Valve Inlet Non-Metallic 0.020 thru hole, Swept Volume 37 µL

- Check Valve Inlet Non-Metallic 0.040 thru hole, Swept Volume 49 µL

- Check Valve Inlet Non-Metallic 0.060 thru hole, Swept Volume 182 µL

Our Non-Metallic Inlet Check Valve is biocompatible and delivers a low cracking pressure. It is made from PEEK and Perfluoroelastomer giving it excellent chemical resistance. Metal free composition makes this check valve perfect for use with corrosive fluids and biological samples. It has a female to male 1/4-28 thread port configuration and a 0.020/0.040/0.060 thru hole.

Technical Specifications

| Thread Port Configuration Flat-Bottom | 1/4-28 |

| Material | PEEK/Perfluoroelastomer |

| Cracking Pressure (psi) | 1 |

| Cracking Pressure (bar) | 0.07 |

| Pressure Rating Max (psi) | 2000 |

| Pressure Rating Max (bar) | 138 |

- Check Valve Inlet Non-Metallic 1/4-28 to 10-32

Our Inlet Non-Metallic Check Valve is biocompatible and delivers a low cracking pressure. It is made from PEEK and Perfluoroelastomer giving it excellent chemical resistance. Metal free composition makes this check valve perfect for use with corrosive fluids and biological samples. It has a female 1/4-28 to 10-32 male thread port configuration and a 0.020 thru hole.

Technical Specifications

| Swept Volume µL | 49 |

| Thread Port Configuration Flat-Bottom | 1/4-28 to 10-32 |

| Material | PEEK/Perfluoroelastomer |

| Cracking Pressure (psi) | 1 |

| Cracking Pressure (bar) | 0.07 |

| Pressure Rating Max (psi) | 2000 |

| Pressure Rating Max (bar) | 138 |

- Check Valve Outlet Non-Metallic 0.020 thru hole, Swept Volume 37 µL

- Check Valve Outlet Non-Metallic 0.040 thru hole, Swept Volume 49 µL

- Check Valve Outlet Non-Metallic 0.060 thru hole, Swept Volume 182 µL

Our Non-Metallic Outlet Check Valve is biocompatible and delivers a low cracking pressure. It is made from PEEK and Perfluoroelastomer giving it excellent chemical resistance. Metal free composition makes this check valve perfect for use with corrosive fluids and biological samples. It has a female to male 1/4-28 thread port configuration and a 0.020/0.040/0.060 thru hole.

Technical Specifications

| Thread Port Configuration Flat-Bottom | 1/4-28 |

| Material | PEEK/Perfluoroelastomer |

| Cracking Pressure (psi) | 1 |

| Cracking Pressure (bar) | 0.07 |

| Pressure Rating Max (psi) | 2000 |

| Pressure Rating Max (bar) | 138 |

- Check Valve Out Non-Metallic 1/4-28 to 10-32

Our Outlet Non-Metallic Check Valve is biocompatible and delivers a low cracking pressure. It is made from PEEK and Perfluoroelastomer giving it excellent chemical resistance. Metal free composition makes this check valve perfect for use with corrosive fluids and biological samples. It has a female 1/4-28 to 10-32 male thread port configuration and a 0.020 thru hole.

Technical Specifications

| Swept Volume µL | 49 |

| Thread Port Configuration Flat-Bottom | 1/4-28 to 10-32 |

| Material | PEEK/Perfluoroelastomer |

| Cracking Pressure (psi) | 1 |

| Cracking Pressure (bar) | 0.07 |

| Pressure Rating Max (psi) | 2000 |

| Pressure Rating Max (bar) | 138 |

- Check Valve Inline Non-Metallic 1/4-28, Thread Port Configuration Flat-Bottom 1/4-28

- Check Valve Inline Non-Metallic 10-32, Thread Port Configuration Coned 1/4-28 to 10/32

Our Inline Non-Metallic Check Valve is biocompatible and delivers a low cracking pressure. It is made from PEEK and Perfluoroelastomer giving it excellent chemical resistance. Metal free composition makes this check valve perfect for use with corrosive fluids and biological samples. It has a female to female 1/4-28 thread port configuration and a 0.020 thru hole.

Technical Specifications

| Swept Volume µL | 34 |

| Material | PEEK/Perfluoroelastomer |

| Cracking Pressure (psi) | 1 |

| Cracking Pressure (bar) | 0.07 |

| Pressure Rating Max (psi) | 2000 |

| Pressure Rating Max (bar) | 138 |

- Micro-Volume Check Valve

Our Micro-Volume Inline Check Valve is biocompatible and delivers a low cracking pressure. It is made from PEEK and Perfluoroelastomer giving it excellent chemical resistance. Metal free composition makes this check valve perfect for use with corrosive fluids and biological samples. It offers a low swept volume. It has a female to female 10-32 thread port configuration and a 0.010 thru hole.

Technical Specifications

| Swept Volume µL | 7.4 |

| Thread Port Configuration Coned | 10-32 |

| Material | PEEK/Perfluoroelastomer |

| Cracking Pressure (psi) | 8 |

| Cracking Pressure (bar) | 0.6 |

| Pressure Rating Max (psi) | 3000 |

| Pressure Rating Max (bar) | 207 |

The Quick-Stop Luer Check Valve is designed to provide inline luer connect/disconnect convenience without the mess and hazard of spills. Just connect the valve assembly to your inline tubing using standard 1/2-28 flat-bottom fittings.

- Luer Adapter Assembly 1/4-28 Female – Male, PEEK

- Luer Adapter Body 1/4-28 Female – Male, PEEK

We designed our Luer Adapters to make it easy for you to create your own quick connect Union or Adapter. We also designed our Luer Adapter Body to make it easy for you to create your own quick connect Union or Adapter. They both have red bodies, black lock hubs, made of PEEK material and Male Luer to Female 1/4-28 threads. Both conforms to ISO requirements for medical luer taper configurations and performance (45psi/3.1 bar).

Technical Specifications

| Colour | Red/Black |

| Thru hole | 0.040 |

| Thru hole | 1.00 |

| Luer to Thread | Male to Female |

| Thread Port Configuration Flat-Bottom | 1/4-28 |

- Quick Stop Luer Check Valve Assembly, Swept Volume 127 µL

- Quick Stop Luer Check Valve, Swept Volume 107 µL

Our Quick-Stop Luer Check Valve Assembly is specifically designed to provide inline luer connect/disconnect convenience while avoiding spills. It offers Check Valve protection with Luer convenience. The check valve is automatically open once the luer connection is engaged, allowing flow in either direction. Disconnecting the luer union causes the check valve to close. It is made from biocompatible PEEK with gold-plated stainless steel spring Check Valve includes (1) P-697 Quick-Stop Luer Check Valve and (1) P-655 Adapter. Our Quick-Stop Luer Check Valve is is made from biocompatible PEEK with gold-plated stainless steel spring.

Technical Specifications

| Material | PEEK |

- Bulkhead Quick Stop Luer Check Valve

Bulkhead Quick-Stop Luer Check Valve Assembly is designed to provide inline luer connect/disconnect convenience while avoiding spills. Get Check Valve protection with Luer convenience with our PEEK Check Valve. It comes a gold-plated stainless steel spring.

Technical Specifications

| Material | PEEK |

Key Industries

- Biopharmaceutical and Biotechnology

- Chemical

- Cosmetics & Personal Care

- Education & Academics

- Food & Beverage

- Medical

- Oil & Gas

- Pharmaceutical

- Powders & Pigments / Coating

IDEX Health & Science is the global authority in fluidics and optics, bringing life to advanced optofluidic technologies with our…

-

SINGAPORE

DKSH Singapore Pte Ltd

625 Lorong 4 Toa Payoh, #03-00

319519 Singapore

Singapore

Download now

How to Disable Pop-Up Blockers for Smooth Downloads

Google Chrome (Version 110 and later):

- Click the three dots (menu) in the top-right corner and select Settings.

- Under Privacy and Security, click Site settings.

- Scroll down to Content and click Pop-ups and redirects.

- Toggle the switch to Allowed or add https://technology-products.dksh.com.sg to the Allow list.

Mozilla Firefox (Version 90 and later):

- Click the three horizontal lines (menu) in the top-right corner and select Settings.

- Go to the Privacy & Security section.

- Scroll to Permissions and uncheck Block pop-up windows for https://technology-products.dksh.com.sg.

Microsoft Edge (Version 110 and later):

- Click the three dots (menu) in the top-right corner and select Settings.

- Scroll down to Cookies and site permissions.

- Under Site permissions, click Pop-ups and redirects.

- Toggle the switch to Allow or add https://technology-products.dksh.com.sg to the Allow list.

Safari (Version 14 and later):

- Open Safari and go to Preferences (from the top menu).

- Select the Websites tab.

- Under Pop-up Windows, select Allow for https://technology-products.dksh.com.sg.