Schleuniger – Process Control

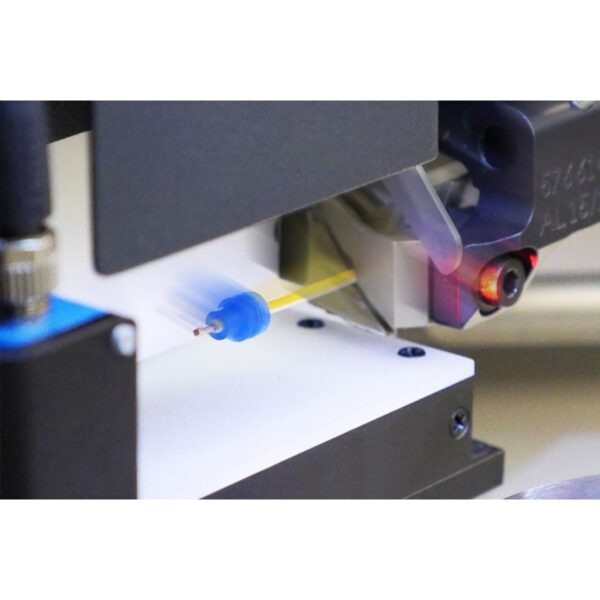

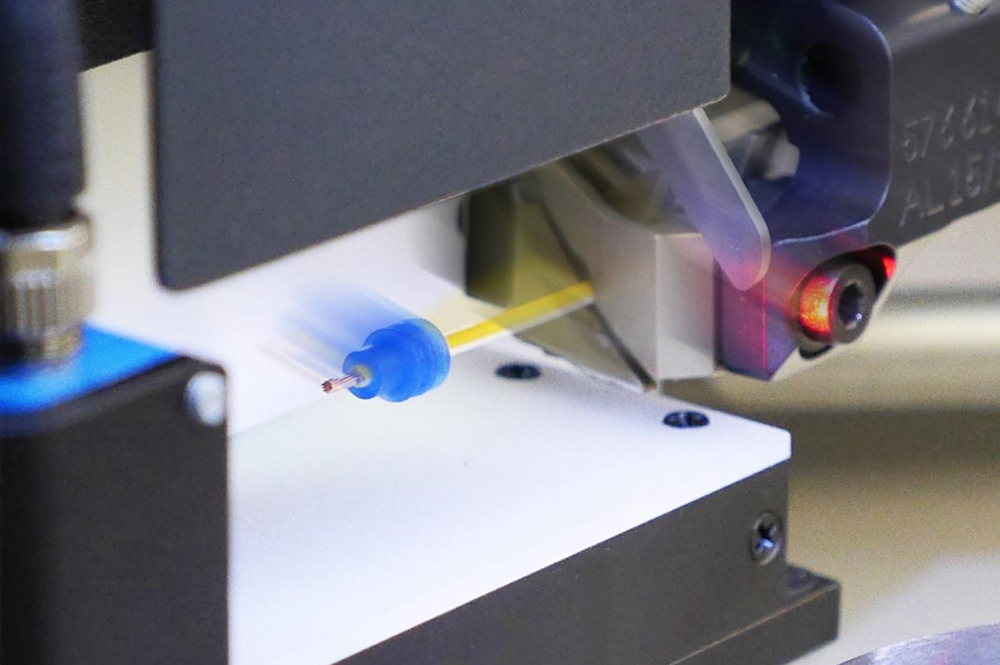

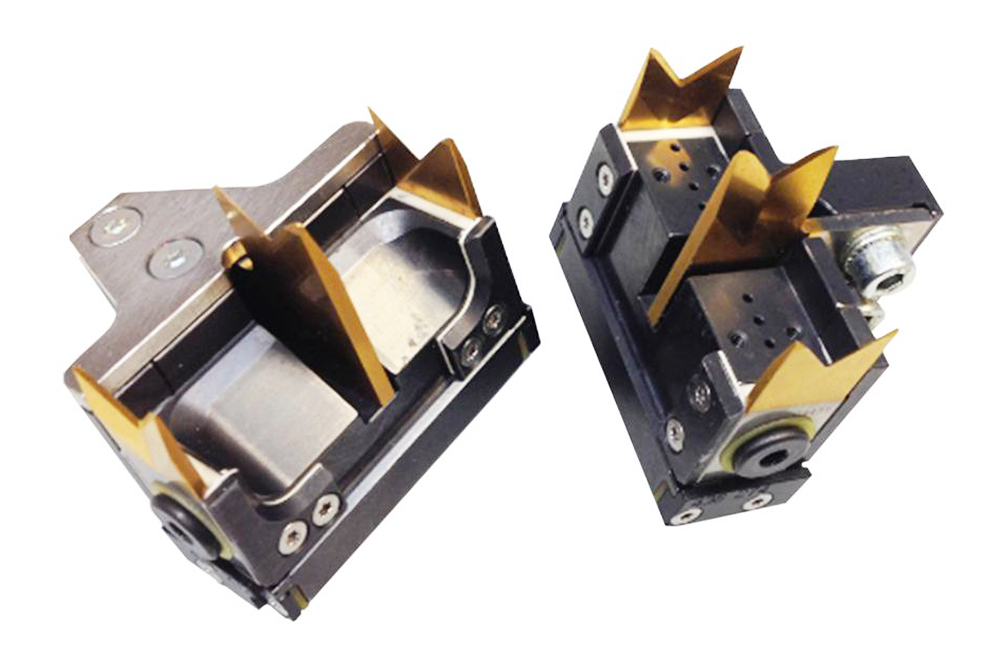

Quality assurance options for your CrimpCenter to meet the most demanding quality standards.Integrated quality assurance systems help prevent errors and detect faulty materials before they impact your business. You can further extend the standard quality assurance functions of your CrimpCenter with Integrated quality assurance systems help prevent errors and detect faulty materials before they impact your business. You can further extend the standard quality assurance functions of your CrimpCenter with additional equipment to meet the most demanding quality standards.

Available Models

Key Industries

- Aerospace

- Die & Mould

- Defense

- Oil & Gas

- Shipbuilding

- Semiconductor, Solar & Electronics

- Education & Academics

- Machinery & Manufacturing

- Automotive

Brand

Schleuniger is a global technology group headquartered in Thun (CH) and a leading supplier to the wire processing and testing industry. All wire processing and automation competencies are bundled under the brand name Schleuniger Group in four centers of competence in Europe and one operations hub in Asia.

Schleuniger Group offers wire processing solutions such as, wire cutting, wire stripping, wire testing and cable cutting. With its wholly-owned but independently managed company, DiIT AG, headquartered in Krailling near Munich (DE), the Schleuniger Group is also a leading player in the area of digitalization and industrial Internet of Things (IoT).