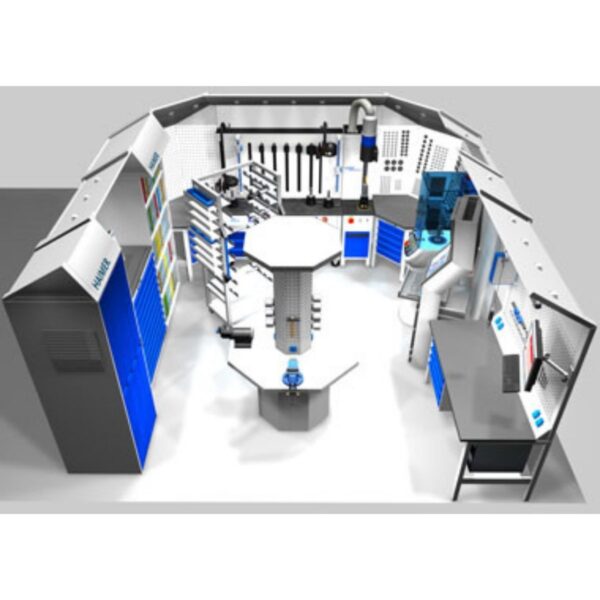

Haas – CNC Machine Tools – VMC, 40 Taper Standard & Drill/Tap/Mill Centers

Every Haas vertical machining center (VMC) provides the features and performance you need, making it the best investment you’ve ever considered – providing more utility, flexibility, and productivity than you’ve ever imagi…

Every Haas vertical machining center (VMC) provides the features and performance you need, making it the best investment you’ve ever considered – providing more utility, flexibility, and productivity than you’ve ever imagined.