Armfield – Miniature-Scale Research & Development Technology – FT102LT Carbonator/Filler

The Armfield FT102X has a well-deserved reputation for being simply the best Carbonator-Filler on the market. The new Armfield FT102LT utilises the same technology and most of the features and benefits, in a smaller, more cost-effective package.

The Armfield FT102X has a well-deserved reputation for being simply the best Carbonator-Filler on the market. The new Armfield FT102LT utilises the same technology and most of the features and benefits, in a smaller, more cost-effective package.

Armfield – Miniature-Scale Research & Development Technology – FT102X Carbonator/Filler and FT104X Filler/Capper

The Armfield FT102X miniature-scale carbonator enables precise and flexible carbonation and filling in the laboratory, dramatically improving the speed with which new products can be developed. The ability to establish precise and reproducible par…

The Armfield FT102X miniature-scale carbonator enables precise and flexible carbonation and filling in the laboratory, dramatically improving the speed with which new products can be developed. The ability to establish precise and reproducible parameters when carbonating in the laboratory can dramatically improve the speed with which new products can be developed.

Armfield – Miniature-Scale Research & Development Technology – FT110 Benchtop Rapid Extractor

The Armfield FT110 Benchtop Rapid Extractor is used to extract the active constituents from small (one litre) samples of materials.

The Armfield FT110 Benchtop Rapid Extractor is used to extract the active constituents from small (one litre) samples of materials.

Armfield – Miniature-Scale Research & Development Technology – FT111 Laboratory-scale Rapid Extractor

Ideally suited to product development purposes, the Armfield FT111 Laboratory-scale Rapid Extractor is used to extract the active constituents from materials in laboratory-scale batch sizes.

Ideally suited to product development purposes, the Armfield FT111 Laboratory-scale Rapid Extractor is used to extract the active constituents from materials in laboratory-scale batch sizes.

Armfield – Miniature-Scale Research & Development Technology – FT140 Mixing Vessels

Armfield FT140 Multipurpose Mixing Vessels are designed and constructed using high-quality hygienic industry standard materials. These tanks are available in three models in varying configurations (see table) and are available in 50l and 100l volu…

Armfield FT140 Multipurpose Mixing Vessels are designed and constructed using high-quality hygienic industry standard materials. These tanks are available in three models in varying configurations (see table) and are available in 50l and 100l volumes. All three models have an internal surface made of AISI 316 stainless steel.

Armfield – Miniature-Scale Research & Development Technology – FT141/FT142 Multifunction Laboratory Mixers

The Armfield FT141 and FT142 are versatile batch processing vessels, the FT142 having UHT capability. They are suitable for high shear mixing, dispersing, homogenising, emulsifying, evaporation and vacuum deaerating.

The Armfield FT141 and FT142 are versatile batch processing vessels, the FT142 having UHT capability. They are suitable for high shear mixing, dispersing, homogenising, emulsifying, evaporation and vacuum deaerating.

Armfield – Miniature-Scale Research & Development Technology – FT17 Cross Flow Membrane Filtration

The Armfield FT17 is a lab-scale system for evaluating membranes in a cross-flow filtration application enabling rapid determination of cross flow filtration performance using a range of membrane types with small product volumes (1 litre). It can …

The Armfield FT17 is a lab-scale system for evaluating membranes in a cross-flow filtration application enabling rapid determination of cross flow filtration performance using a range of membrane types with small product volumes (1 litre). It can also be used in teaching applications to demonstrate features of different membrane types and the effect of varying filtration variables.

Armfield – Miniature-Scale Research & Development Technology – FT174X Modular Miniature-scale HTST/UHT Process System

The FT174X is a modular HTST/UHT processing system designed to treat products at flow rates of 12-40 l/hr or up to 60 l/hr for water (or similar low viscosity products). Standard modules for direct heating (steam injection) or indirect heating (us…

The FT174X is a modular HTST/UHT processing system designed to treat products at flow rates of 12-40 l/hr or up to 60 l/hr for water (or similar low viscosity products). Standard modules for direct heating (steam injection) or indirect heating (using tubular and/or plate heat exchangers), aseptic processing, upstream or downstream homogenisation and additional chilling are available. These, along with many other options, enable multiple modules to be included in the same system, giving high process adaptability by reconfiguration of flexible product hoses, using quick-release connections. The sterilisation options enable it to be linked to an Armfield sterile filling bench to produce aseptic product, even when using long holding tubes and/or downstream homogenisation. As with all Armfield systems, it comes with hygienic fittings throughout as standard, it is easy to clean and very flexible in use. The touchscreen control panel makes it extremely user friendly to configure and monitor processing parameters. The operator is prompted at every stage whenever intervention is required.

Armfield – Miniature-Scale Research & Development Technology – FT18MKII Modular Cross Flow Filtration

The Armfield FT18-MkII is a small pilot-scale cross-flow filtration system designed to operate with a range of membrane module configurations. It can operate with as little as 5-10 litres of material but still give data that is useful for process …

The Armfield FT18-MkII is a small pilot-scale cross-flow filtration system designed to operate with a range of membrane module configurations. It can operate with as little as 5-10 litres of material but still give data that is useful for process scale-up. It can be used over the full range of cross-flow filtration applications from microfiltration through to reverse osmosis. It is the perfect tool to use, following on from flat sheet membrane trials with the FT17, for further process development and scale-up.

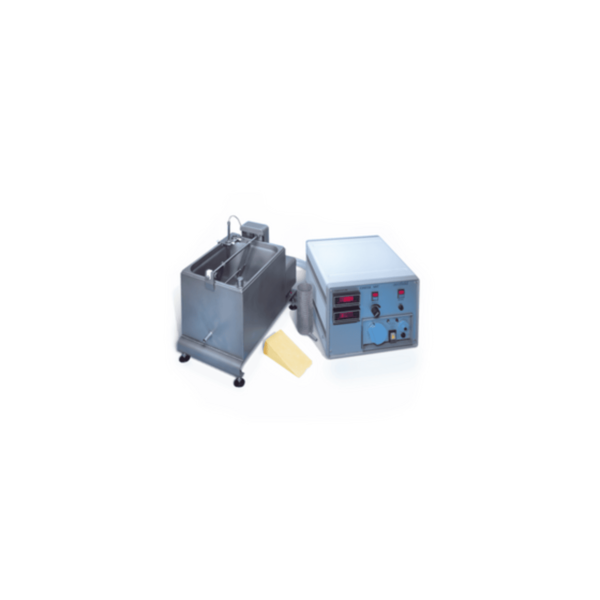

Armfield – Miniature-Scale Research & Development Technology – FT20/FT20A Cheese Vat & Cheese Making Accessories

The Armfield Cheese Vat is designed to provide practical training in the production of cheese by the traditional method. The Armfield Cheese Vat makes an ideal research facility. When making Cheddar type cheese, approximately 1kg of cheese is prod…

The Armfield Cheese Vat is designed to provide practical training in the production of cheese by the traditional method. The Armfield Cheese Vat makes an ideal research facility. When making Cheddar type cheese, approximately 1kg of cheese is produced from a ten-litre batch of milk.

Armfield – Miniature-Scale Research & Development Technology – FT22 Rising Film Evaporator

The costs incurred by the length of time taken, the large quantities of raw materials required and the interruption of the production process mean it is disadvantageous to test new products using full-scale production equipment. The Armfield evapo…

The costs incurred by the length of time taken, the large quantities of raw materials required and the interruption of the production process mean it is disadvantageous to test new products using full-scale production equipment. The Armfield evaporator processes samples as small as two litres under conditions identical to those in production, sufficient to reveal the effect of heating on any ingredients newly introduced to the recipe. As well as investigation of the effect on organoleptic and physico-chemical properties, the equipment can be used to prepare product for taste trials on a daily basis to ensure the quality of incoming raw material is consistent.

Armfield – Miniature-Scale Research & Development Technology – FT25 Scraped Surface Heat Exchanger System

Armfield miniature-scale technology is well established as offering developers the opportunity to run small trials, which provide enough information to enable scale-up to larger plant with confidence. The formulations go through similar physio-che…

Armfield miniature-scale technology is well established as offering developers the opportunity to run small trials, which provide enough information to enable scale-up to larger plant with confidence. The formulations go through similar physio-chemical changes as they would in production plant and real time data logging permits results to be recorded and repeated. The FT25 range of miniature-scale scraped surface heat exchangers has built in control and flexibility with a graphic representation on the membrane technology control panel. The operator can choose the parameters wanted for any particular formulation. The FT25 has a number of configurations according to the use required.

Armfield – Miniature-Scale Research & Development Technology – FT27 CentriPeel Centrifudge

The CentriPeel centrifuge is a basket type separator, designed to save time in R&D operations. The FT27 can be operated at up to 400g, reducing the hours typically required for gravity setting a liquid to just a few minutes. The all stainless …

The CentriPeel centrifuge is a basket type separator, designed to save time in R&D operations. The FT27 can be operated at up to 400g, reducing the hours typically required for gravity setting a liquid to just a few minutes. The all stainless CentriPeel centrifuge is a solid bowl type separator designed to save time in R&D operations. It has a capacity of nine litres per batch and can be operated at up to 400g. It thereby reduces the several hours typically required for gravity setting a liquid to just a few minutes and also gives much improved separation.

Armfield – Miniature-Scale Research & Development Technology – FT29 Batch Solvent Extraction and Desolventising Unit

The FT29 is a batch process unit suitable for teaching and research. Capable of a variety of solid/liquid extractions, it is particularly suitable for leaching edible oils from seeds and desolventising extracted solids and miscella. The Armfield B…

The FT29 is a batch process unit suitable for teaching and research. Capable of a variety of solid/liquid extractions, it is particularly suitable for leaching edible oils from seeds and desolventising extracted solids and miscella. The Armfield Batch Solvent Extraction and Desolventising Unit is a floor-standing, batch-process unit capable of carrying out a variety of solid/liquid extractions. It is particularly suitable for ‘leaching’ edible oils from oil-bearing seeds and desolventising both the extracted solids and the miscella.

Armfield – Miniature-Scale Research & Development Technology – FT40 Multi-purpose Processing Vessel

A vital stage in the preparation of a food product is the accurate addition and correct mixing of the various ingredients that make up the recipe. It is usual that heat will be required, subsequent cooling and chilling are often needed for preserv…

A vital stage in the preparation of a food product is the accurate addition and correct mixing of the various ingredients that make up the recipe. It is usual that heat will be required, subsequent cooling and chilling are often needed for preservation. The Armfield Multi-purpose Processing Vessel is able to carry out these actions with very small quantities of ingredients. The facilities to mix, emulsify, heat, pasteurise, incubate, cool, chill and cure are all built into this purpose-designed unit. As well as preparation of food products for further processing, the facilities allow production of finished products in batch sizes from five to 20 litres.

Armfield – Miniature-Scale Research & Development Technology – FT51 Continuous In-line Deaerator

The Armfield FT51 deaerator unit has been designed to enable small quantities of food and other liquid products to be processed conveniently in the laboratory. It can be used as a standalone batch deaerator or inline with one of the Armfield conti…

The Armfield FT51 deaerator unit has been designed to enable small quantities of food and other liquid products to be processed conveniently in the laboratory. It can be used as a standalone batch deaerator or inline with one of the Armfield continuous processing systems, such as the FT74XTS or the FT174X. The unit is designed to mirror the industrial processes of vacuum deaeration.

Armfield – Miniature-Scale Research & Development Technology – FT52 Clean In Place Unit

The Armfield FT52 has been designed to provide additional cleaning performance for Armfield FT units and other equipment. It consists of a high flow rate stainless steel centrifugal pump mounted on a mobile frame.

The Armfield FT52 has been designed to provide additional cleaning performance for Armfield FT units and other equipment. It consists of a high flow rate stainless steel centrifugal pump mounted on a mobile frame.

Armfield – Miniature-Scale Research & Development Technology – FT66 Neutraliser/Washer/Bleacher

The Armfield FT66 Neutraliser/Washer/Bleacher is a floor-standing batch processing vessel capable of performing the pre-refining stages on small quantities of crude edible oils and facilitates practical research and development.

The Armfield FT66 Neutraliser/Washer/Bleacher is a floor-standing batch processing vessel capable of performing the pre-refining stages on small quantities of crude edible oils and facilitates practical research and development.

Armfield – Miniature-Scale Research & Development Technology – FT67 Hydrogenation Unit

The FT67 is a floor-standing batch processing vessel, used to adjust the degree of saturation of 25-litre batches of edible oils. An integral part of the edible oil processing line, for use in teaching/training and research and development.

The FT67 is a floor-standing batch processing vessel, used to adjust the degree of saturation of 25-litre batches of edible oils. An integral part of the edible oil processing line, for use in teaching/training and research and development.

Armfield – Miniature-Scale Research & Development Technology – FT68 Deodorising Unit

The Armfield FT68 Deodorising Unit is a floor-standing batch processing vessel, suitable for steam stripping of fatty acids from edible oils. For use in teaching/training and research and development.

The Armfield FT68 Deodorising Unit is a floor-standing batch processing vessel, suitable for steam stripping of fatty acids from edible oils. For use in teaching/training and research and development.

Armfield – Miniature-Scale Research & Development Technology – FT74XA HTST/UHT System

The FT74XA is compact, mobile and easy to install. It has an integral pressurized hot water generator and requires only electricity and cooling water to operate making it ideal for confined spaces with limited services such as laboratories. Operat…

The FT74XA is compact, mobile and easy to install. It has an integral pressurized hot water generator and requires only electricity and cooling water to operate making it ideal for confined spaces with limited services such as laboratories. Operation with either plate or tubular heat exchangers means a wide range of product viscosities can be handled. A progressive cavity feed pump ensures that flow rates are independent of viscosity / backpressure changes and allow a maximum operating pressure of 10 bar.

Armfield – Miniature-Scale Research & Development Technology – FT80/FT81 Tall Form Spray Dryer and Tall Form Spray Chiller

The Armfield FT-80 Tall Form Spray Dryer and FT81 Tall Form Spray Chiller have been purposed-designedly to enable laboratory quantities of products to be processed.

The Armfield FT-80 Tall Form Spray Dryer and FT81 Tall Form Spray Chiller have been purposed-designedly to enable laboratory quantities of products to be processed.

Armfield – Miniature-Scale Research & Development Technology – FT83 Sterile Filling System

The Armfield FT83 is the most cost-effective solution for R&D departments to produce sterile packaged samples with an excellent shelf life. As well as a working chamber with a controlled, clean environment, the unit includes the facilities to …

The Armfield FT83 is the most cost-effective solution for R&D departments to produce sterile packaged samples with an excellent shelf life. As well as a working chamber with a controlled, clean environment, the unit includes the facilities to allow all the product paths to be sterilised and for the filling to be controlled in a simple manner.

Armfield – Miniature-Scale Research & Development Technology – FT84-12 Microwave UHT Add-on

The Armfield Microwave UHT /HTST unit has been developed for the rapid heating of various types of viscous, non-viscous and even non-homogeneous products. Product temperatures up to 160°C can be reached. The Armfield FT84-12 can be used with an A…

The Armfield Microwave UHT /HTST unit has been developed for the rapid heating of various types of viscous, non-viscous and even non-homogeneous products. Product temperatures up to 160°C can be reached. The Armfield FT84-12 can be used with an Armfield FT174X, FT74X, FT74XTS or FT94X to provide a rapid microwave final heating stage.