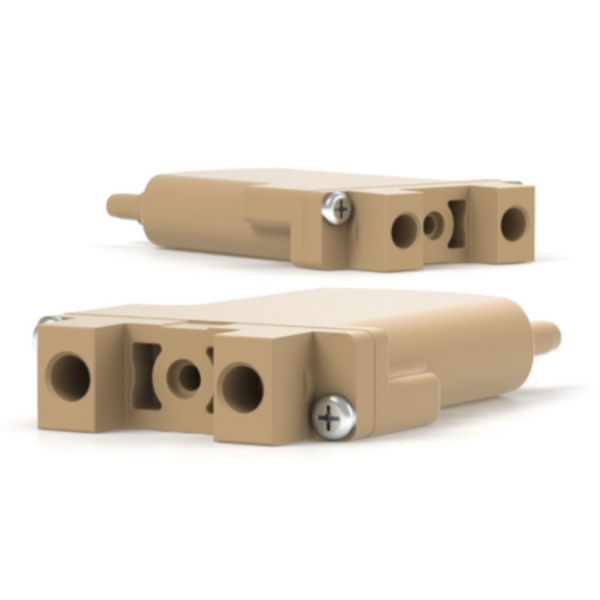

Idex – Connectors – NanoPort Assemblies

NanoPort Assemblies provide consistent fluid connections for chip-based analyses. Our unique design prevents adhesive contamination of the fluid path. Once attached, NanoPort connections can withstand pressures to 1,000 psi (69 bar).

NanoPort Assemblies provide consistent fluid connections for chip-based analyses. Our unique design prevents adhesive contamination of the fluid path. Once attached, NanoPort connections can withstand pressures to 1,000 psi (69 bar).